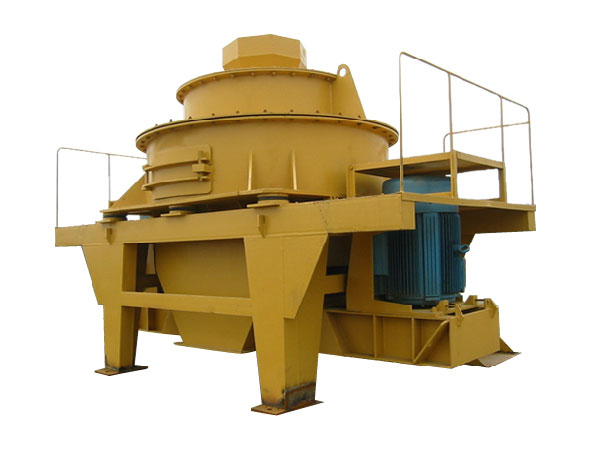

VSI Sand maker

VSI Sand maker

Granite crusher to make sand

“Rock On Rock” And “Rock On Iron” Crushing

In order to meet the crushing demand of different customers, VSI Vertical-shaft Sand Maker takes two crushing methods— “rock on rock” and “rock on iron”(which refer to “rock hitting rock” and “rock hitting iron” respectively). The material liner of “rock on rock” and counter block structure of “rock on iron” are designed specially according to the working condition of the sand-making machine, which greatly promotes the crushing ratio of the sand maker.

Lower Costs In Usage And Maintenance

VSI Vertical-shaft Sand Maker is optimized on some structures and crafts of the impeller. The service life of some wearing parts is prolonged by 30~200% compared to the previous crushing machines under the same usage conditions. VSI Vertical-shaft Sand Maker is configured with simple lifting device. When the sand maker needs maintenance, the lifting of the impeller and the bearing cylinder needs no extra-large lifting devices, greatly lowering the maintenance difficulty of the sand maker.

New Structural Designs Of Key Parts

In order to ensure the overall performance of the sand maker, key parts on VSI Vertical-shaft Sand Maker is optimized on their structures, such as the impeller, the bearing cylinder and the main body. Several national patent technologies owns ensure the high yield, high efficiency and low cost of the crushing machines in crushing operation.

Safer And More Reliable Operation

When designing VSI Sand Maker, the safety and reliability are taken into consideration. The more stable and reliable dual-motor drive and automatic diluted oil lubrication are adopted and at the same time, the gunk and the maintenance platform are optimized to ensure the safety and reliability of operation

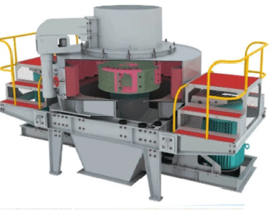

Working Principle

VSI Vertical-shaft Impact Crusher (also known as “Sand Maker”) has two feed modes – “feed at center” and “feed at center & sides”. As for the former mode “feed at center”, materials at the feed hopper firstly pass through the central hole into the high-speed spinning rotor. In the rotor, materials are fully accelerated and thrown outwards from the launching port to collide with a part of materials that freely fall after rebound. Next, materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening. As for the latter mode “feed at center & sides”, firstly, materials at the feed hopper pass through the circular hole. Then, materials are divided into two parts by the distributing tray. One part of materials enter the high-speed rotating impeller while the other part of materials fall from all sides of the tray. Materials in the impeller would be accelerated rapidly and thrown outwards at a high speed to collide with materials falling from all sides of the tray. Next, all materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening.

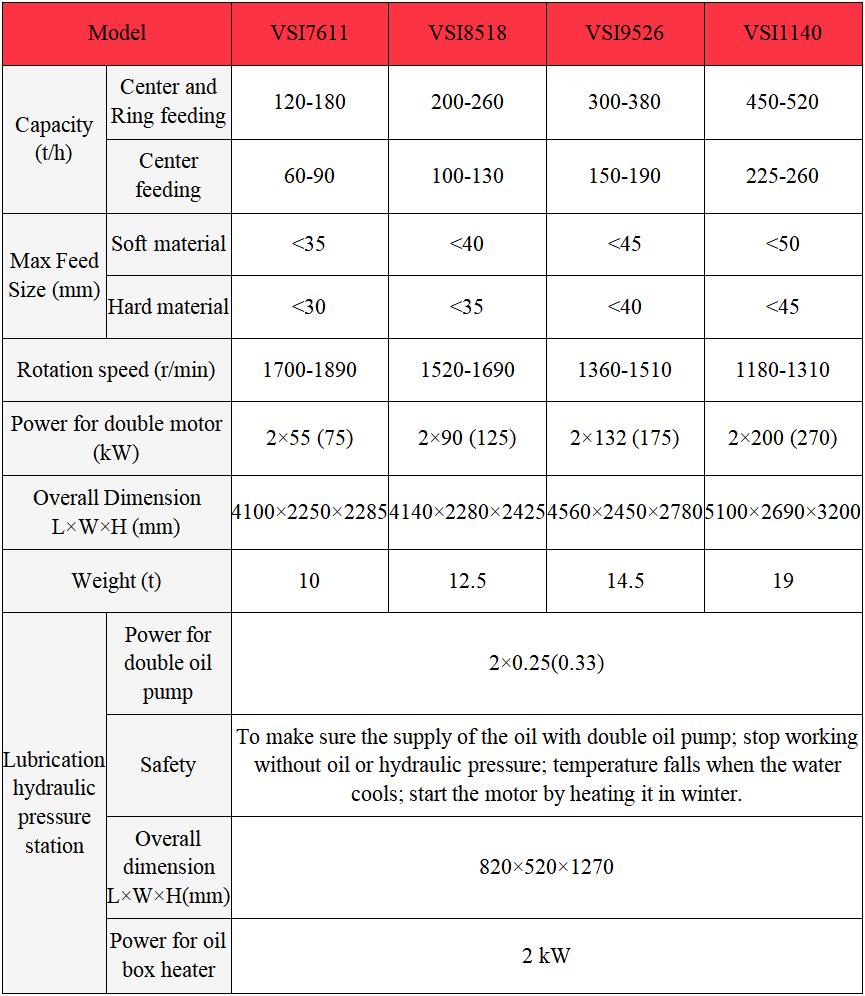

River stone sand makerTechnical parameters

Note:

1.The bulk specific weight is calculated by 1.6t/m³. When the width of the feeding port is above 600mm, it is a large-scale machine while when the width ranges from 300 to 600mm, it is a medium-sized machine.

2.Product pictures and parameters about models, data, performances and specifications on this website are for reference only. There is a chance that may make changes on above-mentioned information. For specific messages, please refer to the real objects and user manuals. Without special instructions, keeps the right to explain all data involved in this website.

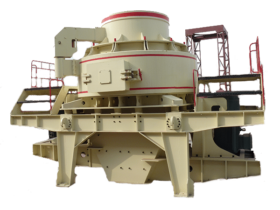

VSI sand maker advantage compared to other fine crusher.

- Large handing capacity and high output-The output of VSI has been stably increased 30% comparing with the traditional equipment under the same motor power.

- Perfect product shape-Cubic products,suitable proportion and adjustable fineness modulus.It fits especially man-made sand and stone reshaping.The effect of making and reshaping sand has been increased 30% compared with the traditional equipment

- Hydraulic door-opened device make the repair in the crushing chamber easily,shorten downtime and save effort. Hydraulic lifting device to lift the hopper,disctributor, impeller and shaft easily,convenient to maintain the machine.

- Multifunctional crushing cavity There are two types of crushing models of this equipment with same crushing cavity, ‘stone beat stone‘ and “stone beat iron”, by changing several parts, the crushing models can be switched to each other. It can adopt to many working coditions and different requirements of crushing and shaping.

- Automatic test,safe and reliable-Vibration display and warning device are set.The machine will be warned to stop working when abnormal phenomenon appears.

- Thinning oil lubricant and automatic-The original German thinning oil lubricant station,double-pump injection system guarantees the oil supply.The machine will stop automatically when there is no oil and pressure.Water cools the oil and electric motor is heated in winter.

Why choose us ?

- Our VSI Sand maker use Deep cavity makes more space for the impeller can improve efficiency greatly.

- High quality alloy wear-resisting body adopt 42CrMo material more wear-resistant, gurantee longer lifetime.

- Main shaft equip imported roller bearing, precise manufacturing makes shaft work stable and solid.

- Multifarious functions, impeller rotating speed has high, medium, low speed can be choosen, can fully meet different requirements, crushing, snad making or shaping request

- The wear parts are stanbard modularity, can keep long term working demand, convenient for maintain.