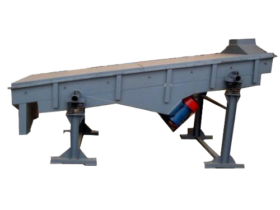

vibarting screen

vibarting screen

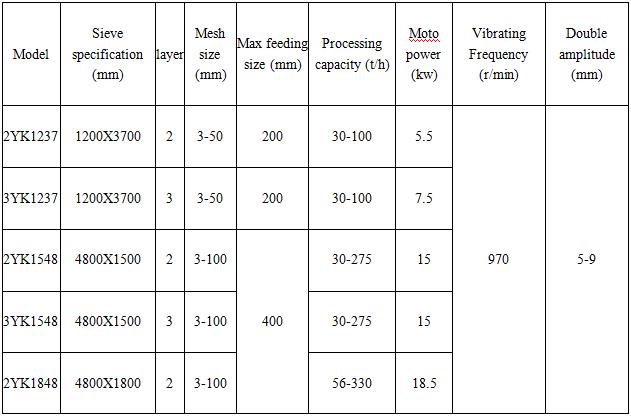

vibrating sieves are used to separate materials into various sizes for further processing or for end use. The material is separated by passing through a vibrating “screen or meshes” which has a number of different sized according to customer’s requirements. The end products can then be used in the building and construction industries. It feature advanced structure, powerful vibrating forces, low vibration noise, easy maintenance, high durability and etc.The vibrating screen with circular motion is specially designed for quarry to separate crushed stone material into different sizes, and is also used as a grading machine in coal dressing, ore dressing, construction material, electric and chemical industries.

Advantage:

A). Reliable quality certified and reaches European standard.

B). Two types of vibrating screen,

C). Unique and advanced design.

D). Powerful vibrating forces, low vibrating noise

- E) Easy to maintain, high durability, etc.

Working principle

The electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.