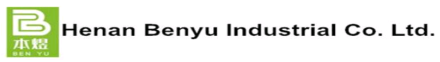

sprial classifier

sprial classifier

Brief Introduction of Mineral Sand Processing Plant:

Spiral classifying equipment is one Types of Classifiers in Mineral Processing ,gold mining equipment,Zircon Sand Separation Machine, based on user requirements, it can be divided into single and double spiral classifier. Depend on specific gravity of solid particles, so different sedimentation velocity in a liquid principle, spiral classifier is a mechanical grading equipment. Feed mill can grind the powder level in the filter, and then use the coarse material spiral piece rotary vane screwed mill feeder to filter out fine material discharged from the overflow tube. Spiral classifier /spiral washer referred grader.

Spiral classifying equipment also called as spiral washer which is widely used in washing silt and stains from manganese ore, iron ore and other low-grade mineral. Also it suitable for scrubbing material which contains tough insoluble clays, conglomerates or soft stone.

This machine drive the spiral stirring shaft depends on speed reducer and rotate in different directions, and the minerals which enter the tank were washed by water and stir strongly by blade. The sewage was overflowed at the end of tank, the cleaned minerals were lifted up along the blade and discharged at the beginning of tank.

Advantages and Characteristics:

-Double durable washing and conveying paddles

-High dealing capacity

-Reliable quality, low power consumption

-Setting up guide

Mineral Sand Processing Plant Types:

We has two type: Single Screw classifier and Double Screen Classifier, can also divided into High Weir Screen Classifier and Submerged Screen Classifier.

Technical Parameters

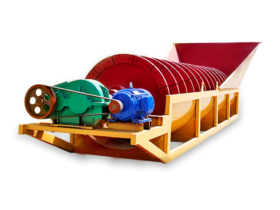

Sand washer can clean and separate the dirt and debris in the sand.Its new sealing structure,overflow weir plate,reliable transmission device ensure the dehydration effciency,suitable for highway,electricity,bulding and ther industries.

Working principle: This sand washer should be installed with an angle of 15 degree,under the water tub, three weir plates form the sediment pool, the screw head is immersed in this pool, the screw is driven by electric motor through reducer rotating continuously, the fresh water is feeding from porous plate at bottom of sediment pool, this machine have three functions of washing, dewatering, classifying.

Washing: The sand is feeding into the sediment pool from the feeding box, with the help of rotating screw blade, the sand is turning, rolling and grinding each other to eliminate impurity and water-air layer around sand to facilitate de-water. The fresh water rising current from the porous plate carries foreign matter to water surface and overflow the weir plate, to finish washing processing.

De-watering: The sand with bigger density is sunken down to tub bottom, the screw blade push this sand upwards, when passing through upper tub of proper length above water level, the water is draining into sedimentpool from another drainage ditch, the de-watered sand is out from the discharging opening.

Classifying: Material classifying is realized by overflowing the fine particle that does not meet the standard requirements. The controlling method is adjusting height of overflowing weir and adjusting speed of screw.