Rotary dryer

Rotary dryer

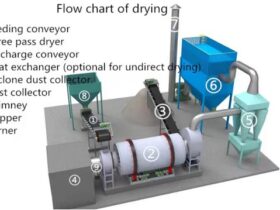

Brief introduction of Bark rotary dryer equipment with high efficiency

The single cylinder rotary dryer is widely used for drying the chalk slags, coal powder, slags, clay and other

materials in the building materials, metallurgy, chemical industry, cement industry. The rotary dryer

has a better adaptability and can dry various materials with a simple and reliable operation.

It is made of rotary body, lifting blade, driving device, supporting device etc.

The dryer has advantages of reasonable structure, high efficiency, low energy consumption and

convenient for transportation.

The rotary dryer can use gas, oil, coal, even wood or biomass as fuel.

Rotary dryer–Features

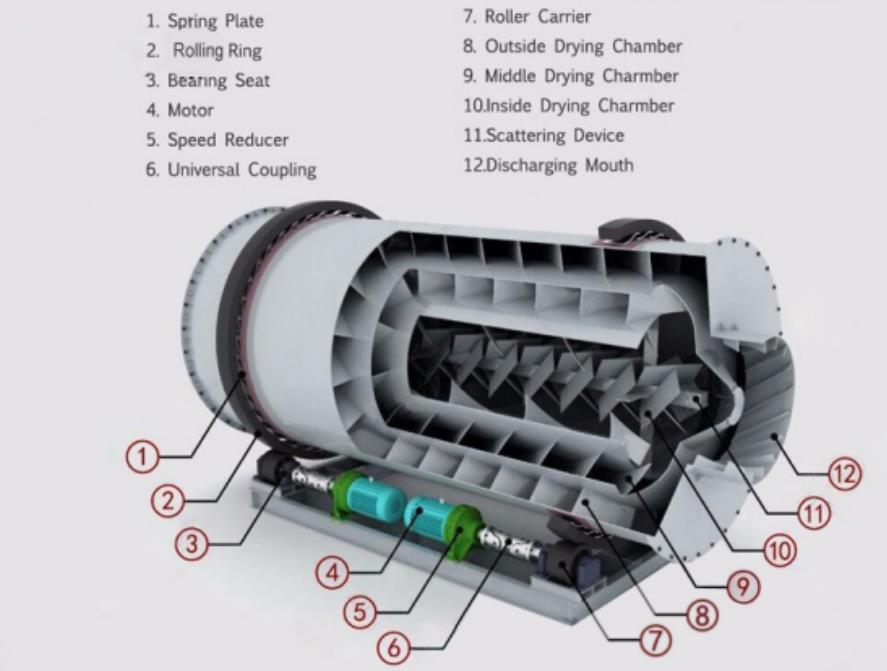

Silica Rotary dryer is mainly composed of cylinder, under frame, feeding and discharging devices,

transmission device, gear cover, etc. (Optional auxiliary equipment includes combustion chamber,

feeder and discharging device, and dust collection equipment). Rotary drier manufactured by us

adopts new lifting plate, which is of functions like guiding, current-sharing, and material rising.

The materials are raised and evenly drop so that they are in full contact with heat for better drying efficiency. Our rotary drier is designed with the best working conditions, which enables it to save 10-15% of energy and increase 10-15% of productivity compared with common dryers.

Features:

- The roller of rotary dryer machine is made of light plate’s stainless steel which has excellent heat

- Good resistance, the inner-wall smooth, can reduce the materials’ wear and tear. Efficient radiator, and with a reasonable lead air duct, so that the hot air can direct contact with materials, greatly improving the drying efficiency, while saving energy.

- Using computer control, we can set different rotary drying temperature and rotary drum drying time according to the drying requirements.

- Large diameter material entrance facilitates the inlet and outlet of materials and greatly improves the drying efficiency.

Aggregate dryer Working principle

Two rolling rings are fixed on the cylinder, and the rolling rings are respectively placed on the two supporting wheel devices. A pair of retaining wheels are also mounted on the roller device at the discharge end to prevent the cylinder from moving axially when rotated. The rotation of the cylinder is realized by the motor of the transmission part driving the pinion gear through the reducer, and the pinion gear meshes with the large gear on the cylinder body, and the large gear wheel is fixed on the cylinder body. At both ends of the cylinder, there are a feeding device and a discharging device respectively, and they are sealed by the sealing device to ensure that the cylinder is sealed without air leakage.

The above technical data is just for reference

| Model | Shell diameter (mm) | Shell length (mm) | Shell volume (m3) | Rotary speed (r/min) | Power(kW) | Weight(t) | Capacity (t/h) |

| φ0.6×6 | 600 | 6000 | 1.7 | 1–8 | 3 | 2.9 | 0.5-1.5 |

| φ0.8×8 | 800 | 8000 | 4 | 1–8 | 4 | 3.5 | 0.8-2.0 |

| φ1×10 | 1000 | 10000 | 7.9 | 1–8 | 5.5 | 6.8 | 1-2.5 |

| φ1.2×6 | 1200 | 6000 | 6.8 | 1–6 | 5.5 | 6.7 | 1.3-3.0 |

| φ1.2×8 | 1200 | 8000 | 9 | 1–6 | 5.5 | 8.5 | 1.5-3.5 |

| φ1.2×10 | 1200 | 10000 | 11.3 | 1–6 | 7.5 | 10.7 | 1.5-4 |

| φ1.2×11.8 | 1200 | 11800 | 13.4 | 1–6 | 7.5 | 12.3 | 2-4 |

| φ1.5×8 | 1500 | 8000 | 14.1 | 1–5 | 11 | 14.8 | 3-5 |

| φ1.5×10 | 1500 | 10000 | 17.7 | 1–5 | 11 | 16 | 5-6 |

| φ1.5×11.8 | 1500 | 11800 | 21 | 1–5 | 15 | 17.5 | 5-7 |

| φ1.5×15 | 1500 | 15000 | 26.5 | 1–5 | 15 | 19.2 | 5-9 |

| φ1.8×10 | 1800 | 10000 | 25.5 | 1–5 | 15 | 18.1 | 7-9 |

| φ1.8×11.8 | 1800 | 11800 | 30 | 1–5 | 18.5 | 20.7 | 7-10 |

| φ1.8×15 | 1800 | 15000 | 38.2 | 1–5 | 18.5 | 26.3 | 8-12 |

| φ1.8×18 | 1800 | 18000 | 45.8 | 1–5 | 22 | 31.2 | 8-15 |

| φ2.2×11.8 | 2200 | 11800 | 44.8 | 1–4 | 22 | 30.5 | 10-15 |

| φ2.2×15 | 2200 | 15000 | 53.2 | 1–4 | 30 | 36.2 | 12-18 |

| φ2.2×18 | 2200 | 18000 | 68.4 | 1–4 | 30 | 43.3 | 15-20 |

Remark:the above technical data is only for reference.

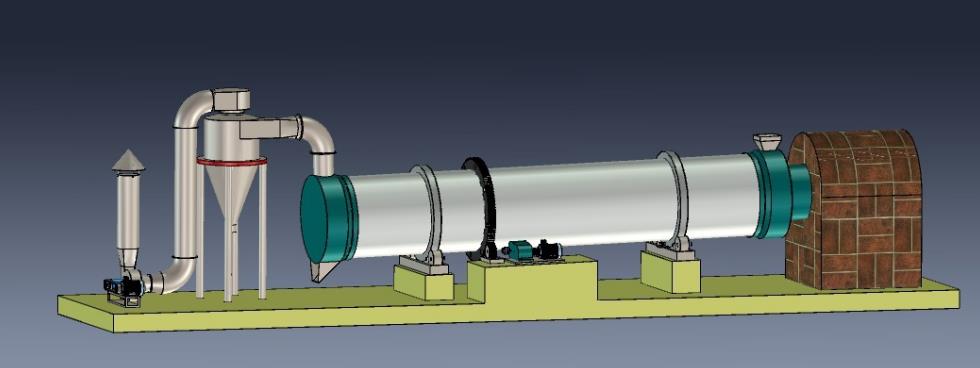

Three cylinder sand dryer for hot sale — Introduction

Three-cylinder rotary dryer is mainly applied for stoving slag, sand, coal, fly ash, iron powder, ore, quartz sand and other particle materials. It has the following characteristics:

- The cylinder protect itself, thermal efficiency can up to 95%.The whole length of the dryer reduced to 50% approximately than mono-cylinder and reduced land investment to 50% approximately

- Cylinder adopts heat-resistant and wear-resistant steel plate welding with long service life and easy maintenance..High thermal efficiency , temperature of outer cylinder is 60or below(temperature of outer mono-cylinder is high to 150°C)

- Low temperature of outlet, long-service of dust removal machine. It also can be directly connected to air box pulse bag filter.

- Without gear and pinion drive, but wheel rotation applied, level operation of the complete machine makes system simple and reasonable.

- Air heater could match boiling furnace, or oil furnace can also be applied, which can dry materials with size below 20mm.

- Final moisture index can be adjusted according to requirements of customers.

The Rotary Drier is widely used in the field of building materials, metallurgies, chemical industry, cement and so on.

Working principle

1.The material first goes into the inside drum, because there are the spiral shape boards fixed in the drum, when the dryer make rotary working, the spiral shape board will stir the material and make the material do movement.

2.When the material reaches the right side of the drum, it will go into the second drum for further drying.

3.The same working principle, the material then goes into outside drum, during the drying working process, the material will make three times drying, so the material can be dried completely in this process.

| Model | Diameter of outer cylinder(m) | Length of outer cylinder (m) | Drum volume(m³) | Rotation speed(r/min) | Max. air flow temperature(℃) | Production capacity(t/h) | Power(kw) |

| 2.0*4m | 2 | 4 | 12.56 | 4-10 | 700-750 | 8-15 | 5.5×2 |

| 2.2*5m | 2.2 | 5 | 18.99 | 4-10 | 700-750 | 12-20 | 5.5×2 |

| 2.5*6m | 2.5 | 6 | 29.43 | 4-10 | 700-750 | 18-28 | 7.5×2 |

| 2.8*6m | 2.8 | 6 | 36.92 | 4-10 | 700-750 | 25-35 | 11×2 |

| 3.0*6m | 3 | 6 | 42.39 | 4-10 | 700-750 | 30-40 | 7.5×4 |

| 3.0*7m | 3 | 7 | 49.45 | 4-10 | 700-750 | 30-45 | 7.5×4 |

| 3.2*7m | 3.2 | 7 | 56.27 | 4-10 | 700-750 | 35-55 | 11×4 |

| 3.6*8m | 3.6 | 8 | 81.39 | 4-10 | 700-750 | 55-75 | 18.5×4 |

| 4.0*10m | 4 | 10 | 125.60 | 4-10 | 700-750 | 70-100 | 22×4 |

Remark:the above technical data is only for reference.

Rotary dryer component list

| No. | Name | Unit | Qty | Remark |

| 1 | Dryer Machine | set | 1 | Material:Q235 |

| 2 | Feeding device | set | 1 | Material:Q235 |

| 3 | Discharging device | set | 1 | Material:Q235 |

| 4 | Lifting board | set | 1 | Complete set |

| 5 | Rolling ring | pcs | 2 | Material:Cast iron |

| 6 | Support device | set | 2 | Material:Cast iron |

| 7 | Transmission Device | set | 1 | Including motor, reducer,motor frame and coupling |

| 8 | Cyclone, ID fan etc. | set | 1 | Including Draught fan, cyclone, pipeline |

| 9 | Pipes | set | 1 | Connection pipe |

| 10 | Elbow | set | 1 | |

| 11 | Accessories | set | 1 | Including flange,bolts and other parts. |