jaw crusher

jaw crusher

what is stone crusher ?

Stone jaw crusher is mainly used for the medium and fine crushing of hard ores and rocks in metallurgy industry, mine industry, chemical industry, cement industry, construction industry, etc. The maximum compression strength of materials to be crushed is 320MPA. PE series jaw crusher is commonly used for primary crushing, and PEX series is used for secondary crushing and fine crushing.

Granite jaw crusher advantage:

1.The unique crushing cavity design makes the wear parts last longer and the crushing ratio is larger. The energy saving of the single machine is 15%-30%.

2.heavy-duty eccentric shaft, high-manganese steel slab and high-cast steel smashing assembly, bearing capacity is stronger and higher.

3.Gasket type discharge adjustment device, large range of discharge adjustment, enhanced

flexibility, to meet a variety of customer needs for stability.

stone crushers for sale application .

For the first process of rock crushing of various mines, various ores with compressive strength not higher than 320 MPa can be processed to medium grain size at one time.

In the mining field, the rough grinding process in the front section of the grinding, the materials in the building materials, metallurgy, chemical, mining, refractory materials, cement, abrasives and other industries are broken.

In the field of infrastructure construction, the crushed stone production of water conservancy and hydropower, highways, high-speed railways, passenger dedicated lines, bridges, airport runways, municipal works, and high-rise buildings is broken.

Rough production of ore such as limestone, rock, river pebble, basalt, granite, quartz stone, tailings, slag, etc., and primary crushing of stone production line and sand production line.

how does a rock crusher work?

The motor drives the belt wheel, and makes moving jaw up and down by eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves, the moving jaw moves towards the fixed jaw. Then the materials can be crushed to reach the crushing target. When the moving jaw is down, the angle between toggle plate and moving jaw becomes smaller. The moving jaw plate leaves the fixed jaw plate under the pulling rod and spring, the final crushed materials will be discharged from the outlet. The moving jaw of the crusher makes periodic crushing and discharging along with the motor to realized batch production.

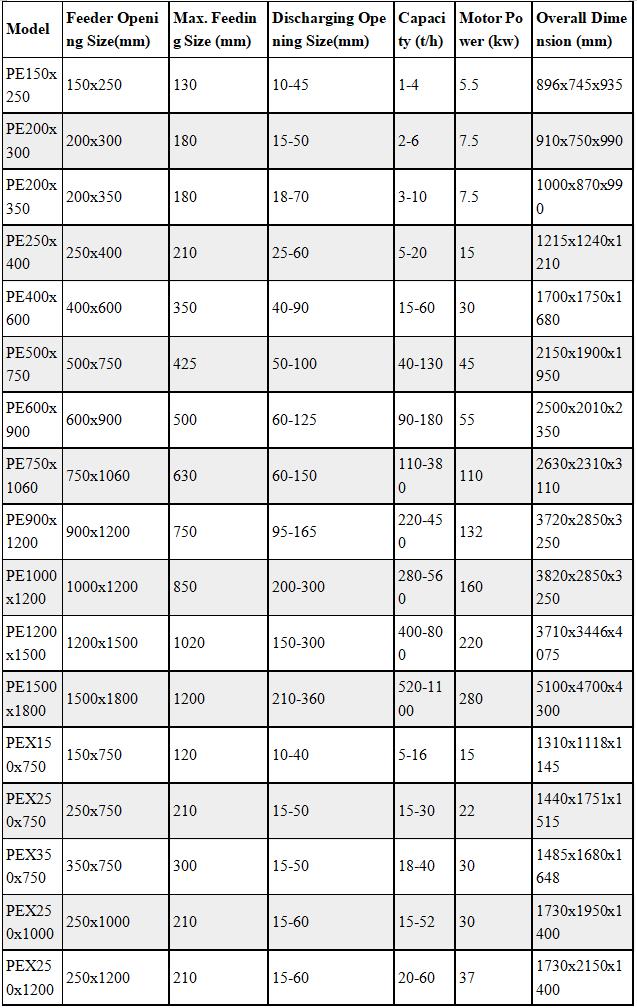

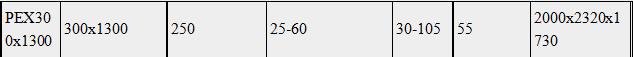

Jaw crusher technical data:

1.Jaw crusher Frame: Q235B steel welding method

2.Movable and fixed jaw plate: high manganese steel, ZGMn13-4 casting tooth-shape side plate.

3.Eccentric shaft: 45# steel precise forged

4.Bearing: China top brand “ Wangfangdian”,Liaoning.

5.Process: casting parts processing–assemble—blasting–no load trial running at least 6 hours– checking–first anti-rust and corrosion painting –last surface painting.stone crusher jaw plate