Hydraulic cone crusher

Hydraulic cone crusher

HP Multi-cylinder Hydraulic Cone Crusher

Based on some design principles of traditional multi-cylinder hydraulic cone crushers like fixed main shaft, eccentric sleeve rotating around main shaft and lamination crushing, HP Multi-cylinder Hydraulic Cone Crusher makes a breakthrough on its structure. After optimization, the structure improves the performance and crushing capability a lot. Meanwhile, the hydraulic lubrication system of HP Cone Crusher not only ensures the stable operation but also makes the system control more intelligent.

Product Features: Higher crushing ratio, bigger processing capacity, better granularity and shape of finished products

Input Size: 0-350mm

Capacity: 45-1200TPH

Material: Granite, diabase, basalt, pebble, limestone, dolomite, metallic ores and non-metallic ores, etc.

Our hydraulic cone crusher advantage:

PLC Integrated Control System Makes Operations Simpler

HP Hydraulic Cone Crusher adopts the advanced PLC electrical system, which can continuously detect the crusher and give alarms, and display various operating parameters. The operator can learn the operating conditions of the crusher in real time. This system not only simplifies the operations of production line and saves the labor cost, but also reduces the operation risk, so that the safety performance of the production line is higher.

Upgraded Structure, Higher Efficiency

Reserving unique structures like the fixed axis and the characteristic that eccentric sleeve rotates around the axis, HP Hydraulic Cone Crusher further optimizes the transmission parts and lubrication and sealing structures. So, this crusher boasts strong holding capacity, bigger installed power, higher efficiency yet lower noises.

The Principle Of Lamination Crushing Brings Better Discharging Size

HP Hydraulic Cone Crusher adopts the principle of lamination crushing. Not only can the crushing efficiency improve, but also the abrasion of vulnerable parts reduces greatly. The finished products are cubic. Meanwhile, the content of qualified fine particles is high enough. Finished products can better serve as high-quality aggregates.

Multiple Cavity Types Meet Various Production Needs

HP Hydraulic Cone Crusher has several kinds of cavities suitable for medium-fine or fine crushing of materials. Users can freely make choices among different cavities by changing only a few spare parts like the lining plate, truly achieving that a crusher serves multiple purposes.

Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates’ cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Working Principle

When a HP Multi-cylinder Hydraulic Cone Crusher works, driven by the motor, the transmission shaft rotates under the action of belt pulley and triangular belt. Next, the transmission shaft drives the eccentric sleeve to make it rotate around the axis. Meanwhile, the eccentric sleeve forces the movable cone to do pendular movement. This movement makes the movable cone and fixed cone sometimes close to, sometimes far away from the rolling wall. Materials are continuously shocked, squeezed and crushed in the crushing cavity between the crushing wall and the rolling wall. Finally, materials are discharged out of the machine when their fineness reaches the discharging standard.

- Convertible multi-cavity&multiple functions.

HPS series multi-cylinder hydraulic cone crusher has several medium crushing and fine crushing cavities, which can be only with

changing relevant several parts as cavity lining plate, etc. It meets the process requirements of medium crushing and fine crushing

better with combining the laminated crushing principle, realizing multiple functions.

Cone crusher frame welding by Q235B thick steel

Material list of cone crusher

Mantle, cone, concave–high manganese steel ZGMn18

With hydraulic cylinder,

Lubrication system,

PLC electrical controlling system

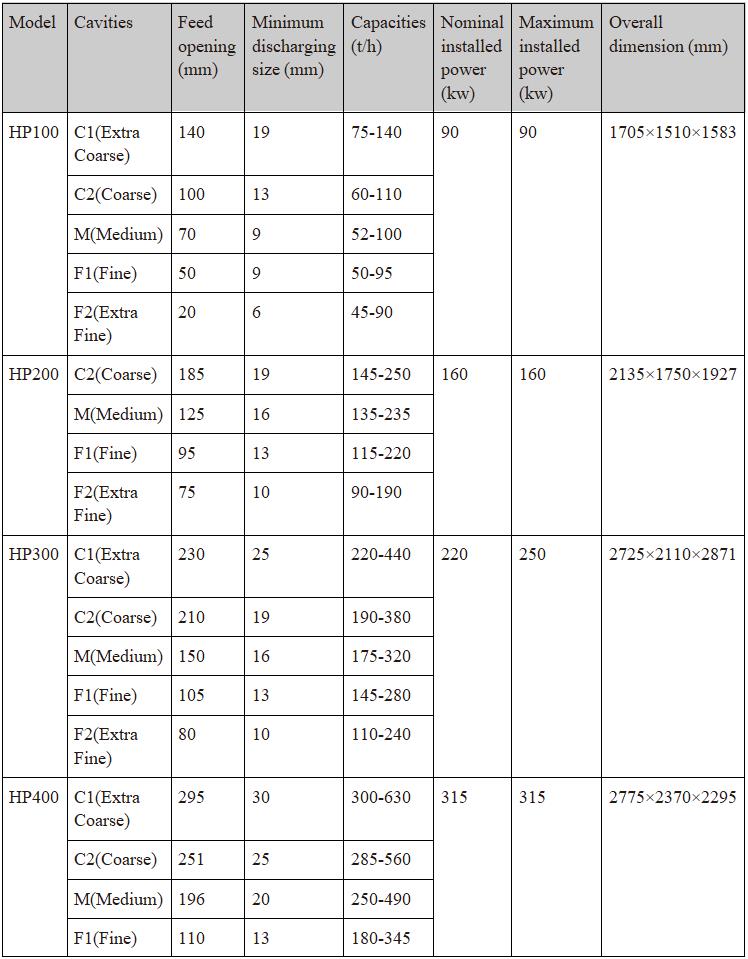

Hydraulic cone crusher Product Parameters

Note:

1.The bulk specific weight is calculated by 1.6t/m³. When the width of the feeding port is above 600mm, it is a large-scale machine while when the width ranges from 300 to 600mm, it is a medium-sized machine.

2.Product pictures and parameters about models, data, performances and specifications on this website are for reference only. There is a chance that DIANYAN may make changes on above-mentioned information. For specific messages, please refer to the real objects and user manuals. Without special instructions, DIANYAN keeps the right to explain all data involved in this website.