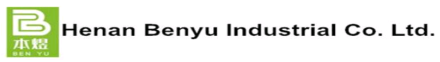

high pressure grinding mill

high pressure grinding mill

Marble grinding mill Application

High-pressure grinder is widely used in mining, meatallurgy, chemical engineering, building materials to grind finely more than 280 kinds of material with Mohs hardness less than 9.3 and the moisture below 6%.The granularity of finished product

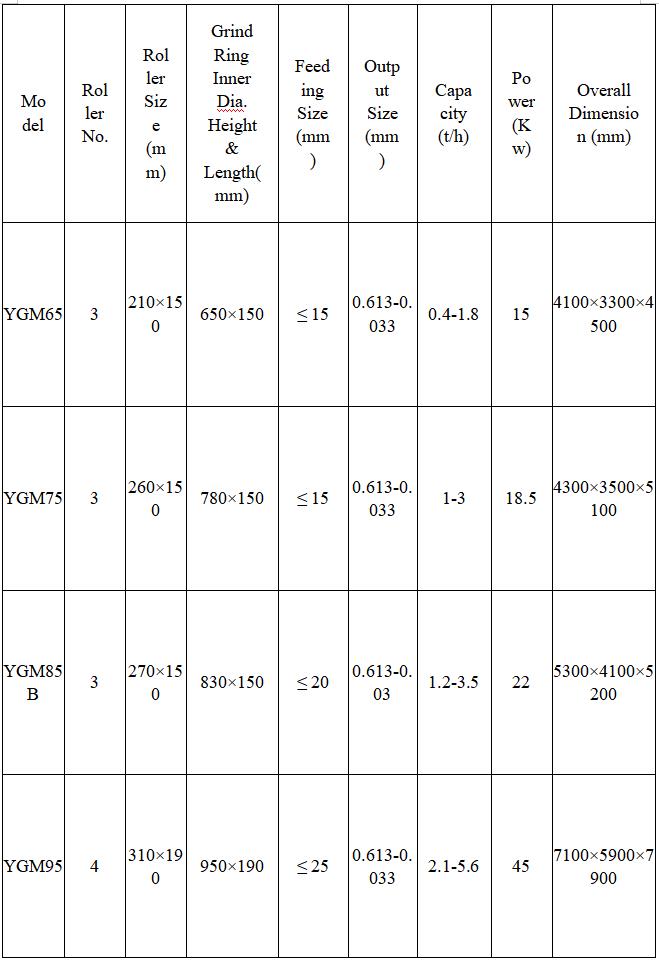

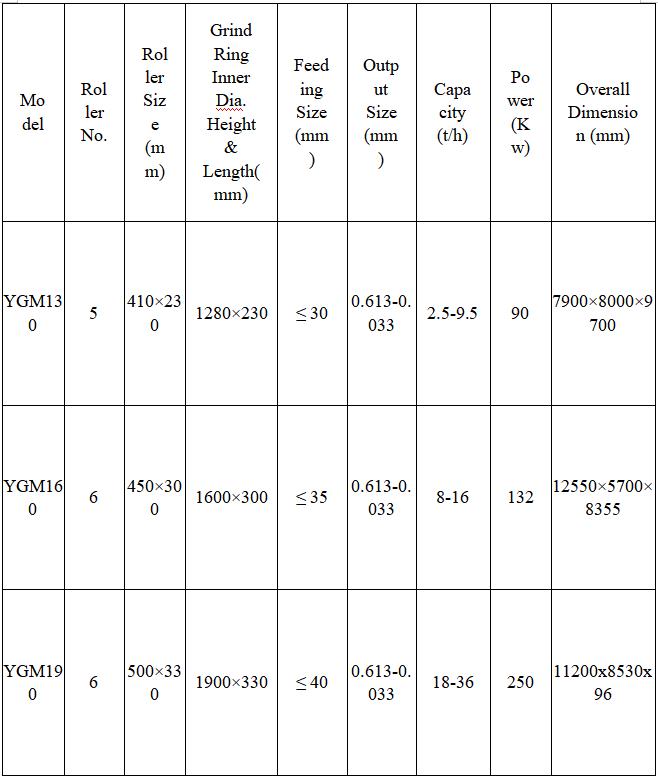

Capacity range:1-30ton.h

Output size:60-500mesh ,0.03-0.5mm

Applicable materials: Stone crusher is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate etc. Different final output size could meet your different needs

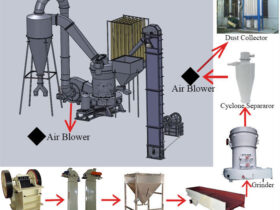

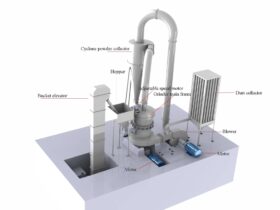

YGM High-pressure grinding Mill has the same working principle as Raymond Mill, but its grinding fitting is furnished with 1000 – 1500 kg high pressure springs.When the machine works, the grinding rollers, under the action of high pressure spring and centrifugal force, rolls close up to grinding ring, its rolling pressure ratio is 1.2 times of Raymond mill given an identical condition, and its output may increase 10% to 20%;

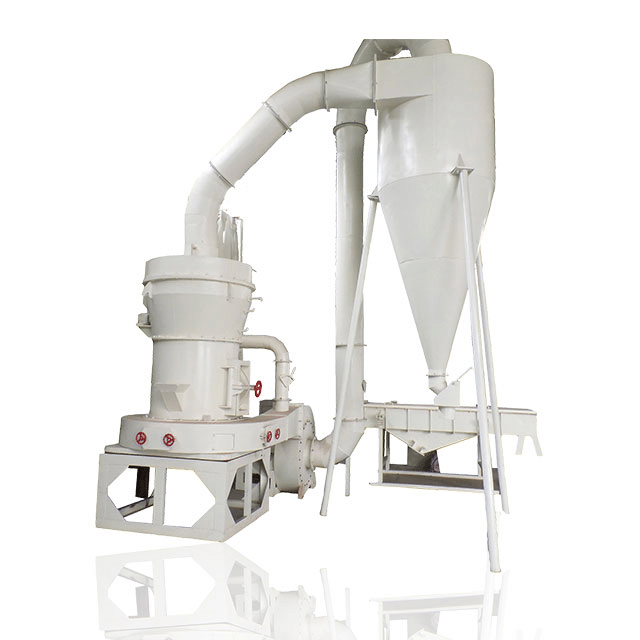

When the material feed into the grinding chamber, ground powder is separated by classifier, which is driven by Electromagnetic speed adjustable motor, can control the rotating speed to control separated output powder fineness. Finally the qualified powder pass the classifier along with the circulation wind of the blower guided to the cyclone collector by connected pipes as final product and large size stuff falls back to the grinder for regrinding. Whole plant under negative pressure in closed circuit, and dust removing by bag filters ensure whole plant good running and environment protection.

Carbon black grinding mill Working principle

- After materials crushed to the desired particle size, enter into the storage hopper by the elevator, and then through vibrating feeder enter into grinding chamber of Raymond mill uniform continuously.

- Due to the centrifugal force when rotating, the rollers swings outward, pressed on the grinding ring, shovel blade scoop up materials, then sent them between grinding roller and grinding ring, due to the grinding roller roller rolling to achieve crushing purpose.

- After grinding material, the powder along with the circulating air which made by blower, is brought into the analysis machine for sorting, coarse material will regrind. Qualified powder along with the air enters into finished product cyclone powder collector, then discharge powder tube, that is finished product.

- In the grinding chamber of mill, since there are certain moisture in the grinded material, when grinding, it will generate heat, moisture evaporates, and the pipe interface of the whole is not tight, the outside air is drawn into making the circulation In the grinding chamber of mill, since there are certain moisture in the grinded material, when grinding, it will generate heat, moisture evaporates, and the pipe interface of the whole is not tight, the outside air is drawn into making the circulation pressure increased to ensure that the mill wok under negative pressure. The increased air flow enter into the dust through the duct, at last enter into the atmosphere after purification.

Q2: What are the requirements for YGM High Pressure Overhang Roll Mill material?

A2:we have a high standard on choosing material of YGM High Pressure Overhang Mill.

1. Using very high grade steel plate (i.e. Q235, Q345) on structuring part;

2. Using wear-resistant steel (i.e. ZG35, ZGMn13, 65Mn, 35CrMo, ZG60Si2CrA) on quick-wear parts;

3. The motor, reducer, bearing, belt, bolts are Chinese top 5 brands;

4. Metallurgy performance must be considered during designing, cutting, bending, fitting&welding.

Q3: What information do we need to provide you the reasonable model and best quotation?

A3: 1. What is the raw material?

2.Raw material maximum feeding size (mm or mesh)?

3. Final products size (mm or mesh) and usage?

4. What is the capacity per hour?