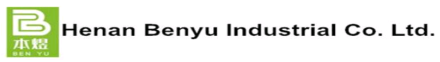

ball mill

ball mill

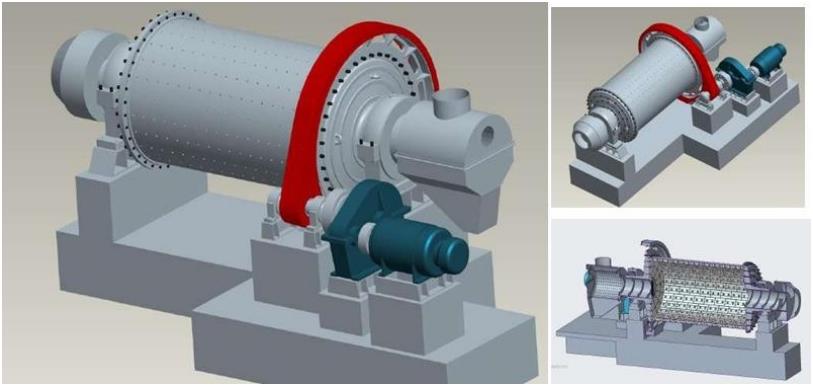

Ball mill Product description

It is key equipment to grind the crushed materials, which is widely used in various industries such as beneficiation, construction materials, chemical industry,such as cement, silicate, refractory material, ferrous metal, nonferrous metal and glass ceramics. It has two ore grinding methods: dry grinding and wet grinding. According to discharge type of finished powder it can be divided into grid type and overflow type. Barrel liner and grinding media can adopt kinds of materials like alloy steel , stainless steel , rubber, ceramic etc.

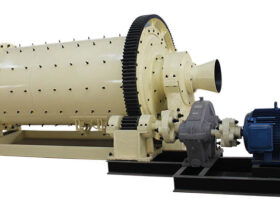

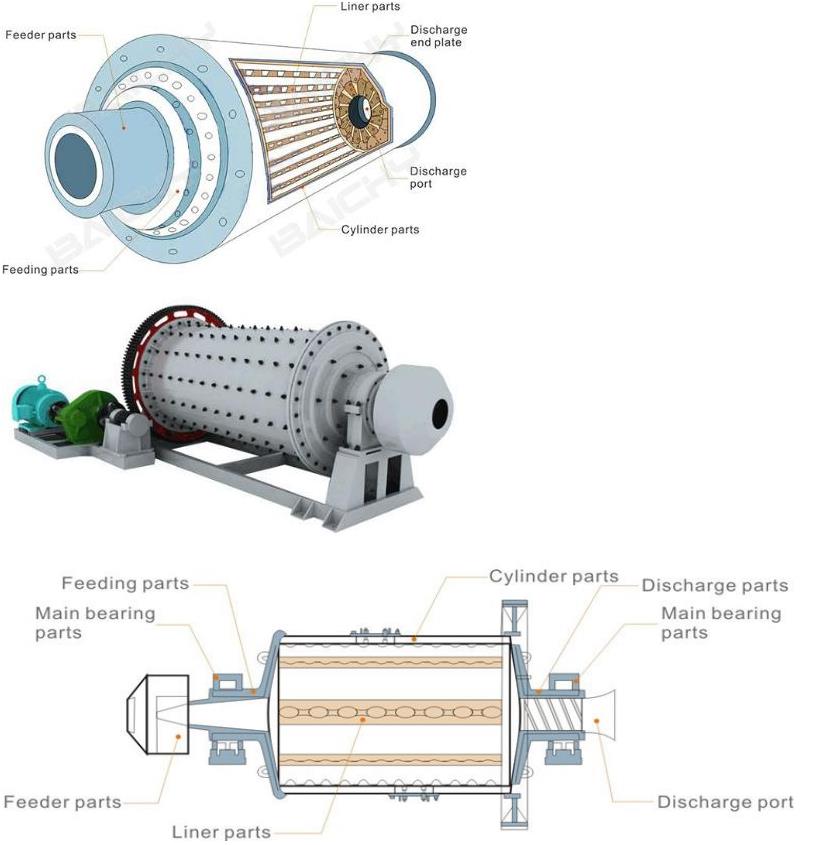

How ball mill works?

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner or ripple liner and different specifications of balls in the chamber. The centrifugal force caused by rotation of barrel brings the balls to a certain height to impact and grind the materials.

Final powder fineness depends on raw material hardness under processing, and the length of ball mill, the longer time running in ball mill, the finer powder would be. According to fineness specifications, barrel can equip partition grids plate materials after ground in first chamber then enter into secondary chamber for further grinding final fine powder would be discharged from discharging grids plate, end the milling process.

Iron ore ball mill working principle

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner or ripple liner and different specifications of balls in the chamber. The centrifugal force caused by rotation of barrel brings the balls to a certain height to impact and grind the materials.

Final powder fineness depends on raw material hardness under processing, and the length of ball mill, the longer time running in ball mill, the finer powder would be. According to fineness specifications, barrel can equip partition grids plate materials after ground in first chamber then enter into secondary chamber for further grinding final fine powder would be discharged from discharging grids plate, end the milling process.

According to customer different requires on final powder fineness, we would suggest and design most suitable solution for you.

The finer powder output, the longer cylinder would be. Sometimes also need to add partition grids plate for more grinding chambers to acheive fine powder.

Remarks

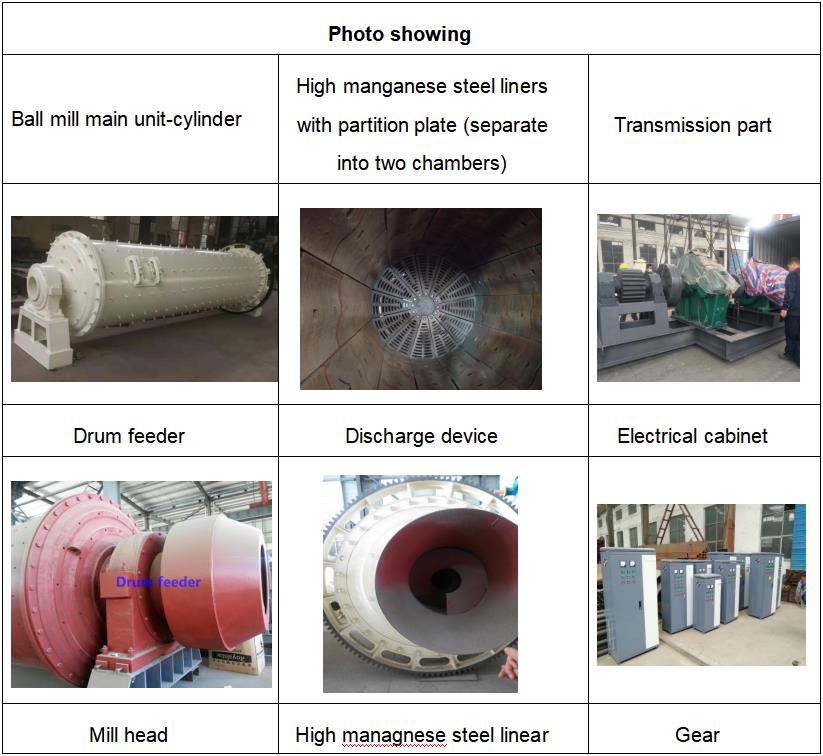

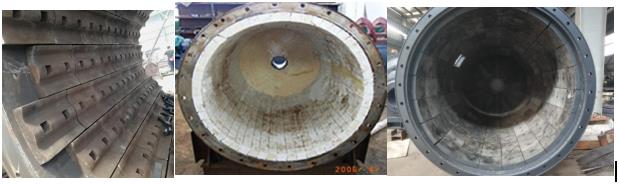

Material feed by drum feeder, with linear can adopt high manganese steel linear or high alumina linear, with motor, reducer, whole set.

▲Liner material: high manganese steel material

▲Partition plate material: high manganese steel material

▲Foundation base.

▲Big gear, pinion, coupling, motor, reducer.

How many type of the ball mill ?

There are Two type grinding process of ball mill

Dry type Grindng ball mill is Mainly for dry powder or fine sand making.

Whole plant mainly consist of bucket elevator, powder classifier (for optional), dust collector, blower. whole set under negative pressure running.

Wet type Grindng ball mill is Mainly for different ore grinding and Slurry making.

Whole plant mainly consist of ball mill, spiral classifier, hydrocyclone, pumps,etc. Widely used for mineral beneficiation plant like copper, gold, lead, etc kinds of ores fine grinding and beneficiation process.

How many type grinding balls and liner of ball mill ?

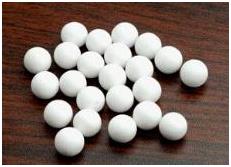

Usually ,there are three type balls media ,such as alloy steel,ceramic balls,Stainless steel balls.

Generally balls fills about 40%-45% in wet process, and in dry process will be a little less about 35-40% of net value of ball mill.

According to experience and testing choose best balls and material total filling quantity. Generally not less than 1/2.

Alloy steel material:

- Cr content 7%-10%、HRC≥50, Meidum chrome ally steel balls.

- Cr Chrome content 10%-14%、HRC≥58,High chrome alloy steel balls, is most popular with high wearance resistance, widely used.

- Cr Chrome content >14%, HRC >58, Special high chrome alloy steel balls, adapt to large consumption industry, price higest.

High alumina balls main element is Al2O3, about 92%-95%, density 36.4-37.1g/cm3.

Stainless steel use 304 (best) or 201#.

According to powder fineness requirements decide balls sizes matched. Generally fist time large ball mill( ф120mm—ф90mm)occupy 30%–40%、Medium (80mm-60mm) occupy 40%–30%、small balls(ф50 and ф30mm)occupy30%,but for wet grinding mainly through grinding rather than impacting, so will have few large balls(~20%) more small balls (~50%)

According to raw material, can adopt alloy steel ZGMn13-4 high manganese steel, ceramic liner,or others depend on customer requirements. like cement industry use high chrome alloy casting linear for more wea resistance.

What is the ball mill wear part ?

The wear part is usually balls,liner,gear etc.